CNC Turning / Milling

CNC Turning / Milling Services

Avanti Engineering is a leading provider of CNC milling and turning machining services. We specialize in utilizing the latest CAD technology to create precise and customized parts. Our team of experts leverages their extensive experience and expertise to ensure that parts meet your exact needs and specifications.

With state-of-the-art CNC multi-axis machining centers, Avanti Engineering can perform a wide range of tasks at high speeds such as:

- Milling

- Drilling

- Tapping

- Small plate vertical machining

- Turning

Our CNC machining experts utilize the most advanced CAD technology available to create a comprehensive and detailed visualization of the parts during the design phase. By harnessing the power of this cutting-edge software, we are able to simulate and refine every aspect of the part, ensuring its accuracy and functionality.

Once the design phase is complete, our focus shifts to the CAM software, which seamlessly guides the machining and milling process. This software acts as the brain behind the operation, providing precise instructions to our state-of-the-art CNC machines. These machines, equipped with high-precision tools, execute the instructions with utmost accuracy and efficiency.

The synergy between our expert team and the advanced technology we employ results in the production of parts that perfectly match your specific requirements and specifications. By utilizing our CNC machining capabilities, we can guarantee that each part is crafted with unparalleled precision and attention to detail.

CNC Machining Advantages

One of the key advantages of our CNC machines is their ability to replicate the same specifications with utmost precision. This means that whether you require a single component or a large batch, we can consistently deliver identical parts without any variation between production runs. Traditional machining methods often suffer from inconsistencies and deviations, making it challenging to reproduce the exact same part over time. Our CNC machines eliminate this problem, providing you with peace of mind and seamless continuity in your operations.

By relying on computer control, our machines execute complex operations with exceptional accuracy. The automated nature of CNC machining ensures that each component is crafted with attention to detail, resulting in superior quality and functionality. This precision also enables us to achieve intricate designs and complex geometries that would be challenging or impossible to achieve through conventional machining methods.

Our CNC machines offer optimal efficiency, saving valuable time and resources. With computer programming controlling the manufacturing process, we can achieve faster production speeds without compromising on quality. This allows us to meet tight deadlines and handle high-volume orders with ease, ensuring timely delivery of your products.

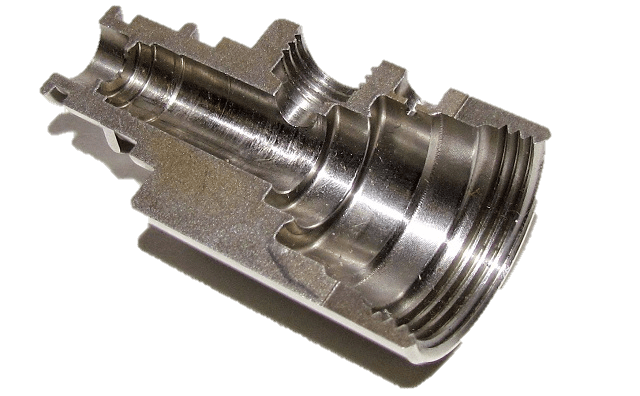

CNC Milling

-

CNC milling is a crucial process in which a rotating cutting tool removes material from a workpiece to create a desired shape or form. This technique allows for precise and accurate production of various components, ranging from simple to intricate designs. Our experienced technicians are skilled in utilizing state-of-the-art CNC milling machines to deliver high-quality results every time.

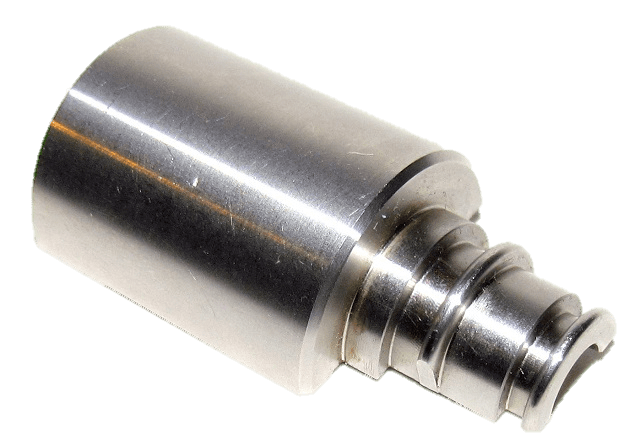

CNC Turning

-

Similarly, CNC turning is another vital process in which a workpiece is rotated rapidly while a cutting tool shapes it to the desired specifications. This method is particularly suitable for cylindrical or rounded components. At Avanti Engineering, we have a wide range of CNC turning machines that can handle diverse materials and intricate designs, ensuring optimal precision and efficiency.

Materials

Our precision milling and machining services can produce parts in many different materials, including plastic, metals (ferrous and non-ferrous), composite materials and beyond. We understand the importance of maintaining the integrity and intricacy of such materials, ensuring that the final products meet the highest standards.

Industry

No matter what industry you belong to – be it aerospace, medical, automotive, electronics, or any other niche – Avanti Engineering is here to meet your turning and milling needs. Our team of experts boasts years of experience, working closely with clients from various sectors. This wealth of knowledge allows us to offer tailored solutions that cater to your specific requirements.

CNC Milling and Turning Services

When it comes to CNC milling and turning, we specialize in providing tailored solutions to our clients. Our team works closely with each customer, ensuring that we understand their specific needs and objectives. Whether it is a complex production run or a design consultation, we are committed to delivering top-notch service that exceeds expectations.

At Avanti Engineering, we offer comprehensive design and consulting services. Our team of experts can assist you in refining your product designs, optimizing manufacturing processes, and identifying cost-saving opportunities. By working closely with our clients, we aim to provide tailored solutions that not only meet their immediate needs but also contribute to long-term success.

We pride ourselves on our ability to understand and address the unique challenges faced by our clients. Whether it’s CNC milling, turning, design, or consulting, we are here to provide exceptional service and ensure customer satisfaction. Reach out to Avanti Engineering today, and let us help you achieve your production goals efficiently and cost-effectively.

Machining Capabilities

Automatic Bar Machining

Capacity for parts from 1/16" to 2 5/8”

CNC Turning & Milling

CNC multi-axis machining centers for superior speed & flexibility

Custom Machining

Multi Spindle Machining

Screw Machine Products

Precision components from a broad variety of materials & Equipment

Swiss Machining

High Volume Machining

CNC Machining

Machining from Bar stock using auto magazine bar loaders for increased running efficiency & up to 11 axis of motion.

11 Axis Machining

Multi-Axis Multi-spindle technology for completing complex parts efficiently in one operation. C=0 sampling plan & equipment versatility provide one-stop shop capability for a variety of applications.

Ask a Question!

Avanti Engineering, Inc.

200 West Lake Drive

Glendale Hts, Illinois 60139

Phone: (630) 260-1333

Fax: (630) 260-1762

Looking for screw machine products or CNC Machining?

we have you covered!

AVANTI ENGINEERING, INC.

200 W. Lake Dr, Glendale Heights, IL 60139

(630) 260-1333

© 2023 Avanti Engineering. All Rights Reserved.